An ultrasonic flow measurement can be solved in two ways: either with the inline or with the clamp-on variant. With the inline variant, sensors are built into the pipe through which the medium to be measured flows. This method offers maximum accuracy, but has the disadvantage that the process must be interrupted during installation. In addition, measurements are disrupted as soon as there is a slightly higher proportion of air bubbles and solid particles in the medium.

For a simple and cost-effective installation, the clamp-on flow solution is ideal.

What can it measure?

All electrically conductive and non-conductive liquids can be measured. The following table gives examples of possible and non-possible media.

|

Can be measured |

Cannot be measured |

|

Oil |

Steam (due to pressure and temperature conditions) |

|

Water and deionized water |

Glacial acetic acid (the acid has low sonic conductivity) |

|

Water in district heating |

|

|

Gas |

What are the advantages of the clamp-on method?

An ultrasonic flow measurement using the clamp-on method offers very simple installation. As the name suggests, the measuring devices are attached to a tube from the outside, either with a buckle or magnetically. This type of non-contact measurement has no wearing parts and is therefore very durable.

In general, air bubbles and solids in the medium can interfere with the measurement. With the inline variant, a maximum of 3% of such interference may occur, otherwise the sensor can be blocked. The clamp-on version, on the other hand, tolerates 12% air bubbles and solid particles. As long as a water front reaches the sensors, the flow can be measured at the clamp-on.

It also works regardless of conductivity, viscosity, temperature, density or pressure. The highly accurate measurement results are easy to read on the digital display.

How does flow measurement work with the clamp-on variant?

Imagine two people meeting each other on the same treadmill at the airport. Person A walks in the direction of travel of the treadmill, while person B walks in the opposite direction. Person A is faster than person B. This concept can be applied to ultrasonic waves in a pipe with flowing medium. Ultrasonic waves moving in the direction of flow are faster than those moving against the flow.

If you have now attached two measuring devices to a pipe, you can let them communicate with each other. Here, ultrasonic waves are sent and received using the piezoelectric effect. The greater the difference between the two measured values, the faster the medium is moving.

If you offset the pipe diameter with the temperature of the medium and the speed of sound, you get exact volume data, as well as viscosity and density.

How is the assembly?

Assembly is very easy and does not disrupt the process as the measuring devices are attached from the outside. It is attached using magnets, possibly using buckles that go around the tube. It can be mounted on both a vertical and a horizontal flow. Depending on conditions, a direct mode or reflect mode rig can be installed.

|

Direct mode (Z) |

Reflect mode (V) |

|

|

|

MUST be selected if... - Measured on old pipes (existing deposits can interfere with the ultrasonic signal) - There is not enough installation length along the pipe - The following pipe materials are present (ultrasonic signal is not reflected): fiberglass, PVC, glass; polyethylenes |

MAY be chosen if... - Possible. - There is enough space on the installation route - The following materials are present (ultrasonic signal is reflected): steel, stainless steel, nickel, brass, copper, titanium |

There is also the option to choose between multi-channel measurement and multi-path measurement.

|

Multi-channel measurement |

Multi-path measurement |

|

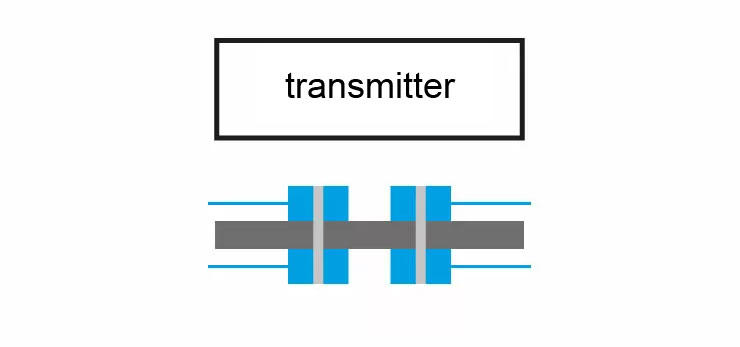

1 transmitter processes n measuring points |

1 transmitter processes n pairs of sensors |

|

|

|

It is measured at two different measuring points, independently of each other. Measurement results are obtained from two measurement locations. |

A transmitter measures at a point with n x pairs of sensors and calculates the mean value. |

SITRANS FS290 flexible, versatile, practical

- Check metering, temporary and test measurements

- Compensation of flow disturbances through the anomaly compensation

- Long battery life, simple battery replacement

- Measurement accuracy of 1% under good conditions

Datenblatt Datenblatt

|

The battery or mains powered SITRANS FUE950 is a universal custody transfer approved energy calculator. It is designed for use in hot water, chilled water and cooling/heating applications. The calculator has a modular construction which means that it can be fitted with optional output modules when it is ordered. These include a pulse output, pulse input, current output and an M-Bus add-on module. If needed, the necessary temperature sensor pair and pockets can be ordered along with the calculator.

The SITRANS FUE950 can be used with SITRANS FUS380, SITRANS FUE380, SITRANS FM MAG 5000, SITRANS FM MAG 6000, SITRANS FM MAG 8000 and SITRANS FS220. Application Examples: District heating applications, Chilled water applications, Combined cooling/heating applications

Datasheet Datasheet

|